The Makkah Royal Clock Tower

The biggest tower clock in the world

The idea of implementing the central skyscraper of the King Abdul Aziz Endowment Project in Mecca as the tallest clock tower in the world came about during the building of a group of seven hotel towers at the gate to the Great Mosque.The construction calculations for the towers had already been completed when, in late 2006, SL Rasch was asked to design the huge clock add-on. The specification: the tower top was to weigh no more than 82,000 tonnes. The result is a highly complex design that combines contemporary composite materials with traditional elements of Islamic art as if it were the most natural thing in the world.

Frame structure

Frame structure

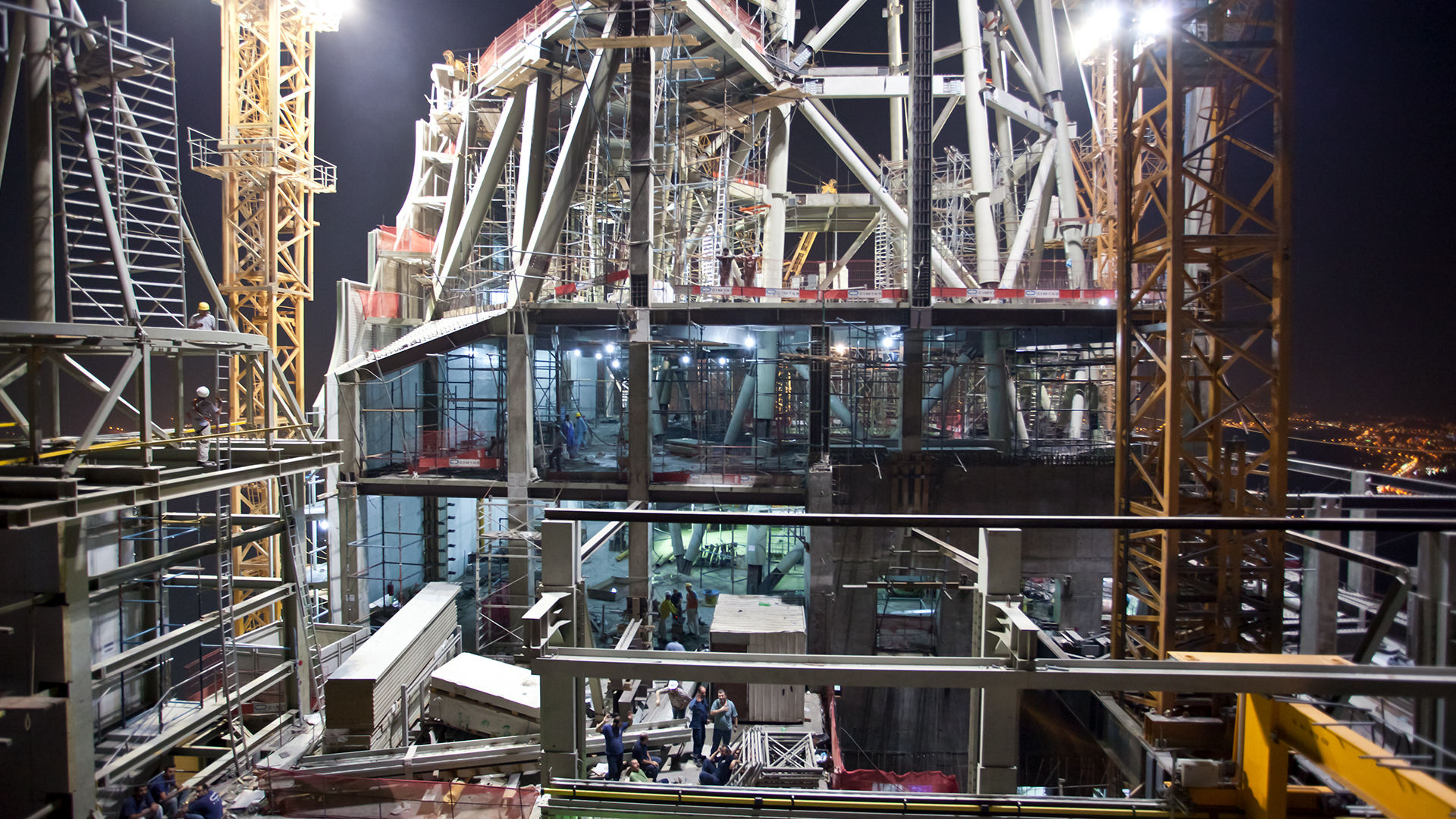

The basic frame of the clock tower’s load-bearing structure consists of four V-shaped supports. Above the clock, the columns merge into a conical steel beam that follows the contours of the spire and transfers the loads directly from top to bottom.

To ensure maximum load capacity and keep weight to a minimum, the civil engineering team developed a frame structure with composite profiles made of high-strength steel and concrete. The enormous faces and hands of the clock, as well as the panels in Arabic script above it, were then attached to this frame. They are made of innovative composite materials that were covered with custom-made glass tiles. In order to meet the project requirements, an automated production system was set up: state-of-the-art computer software made it possible to prefabricate and preassemble the composite elements, including the mosaic tiles and light sources.

Glass mosaics and innovative composites

Glass mosaics and innovative composites

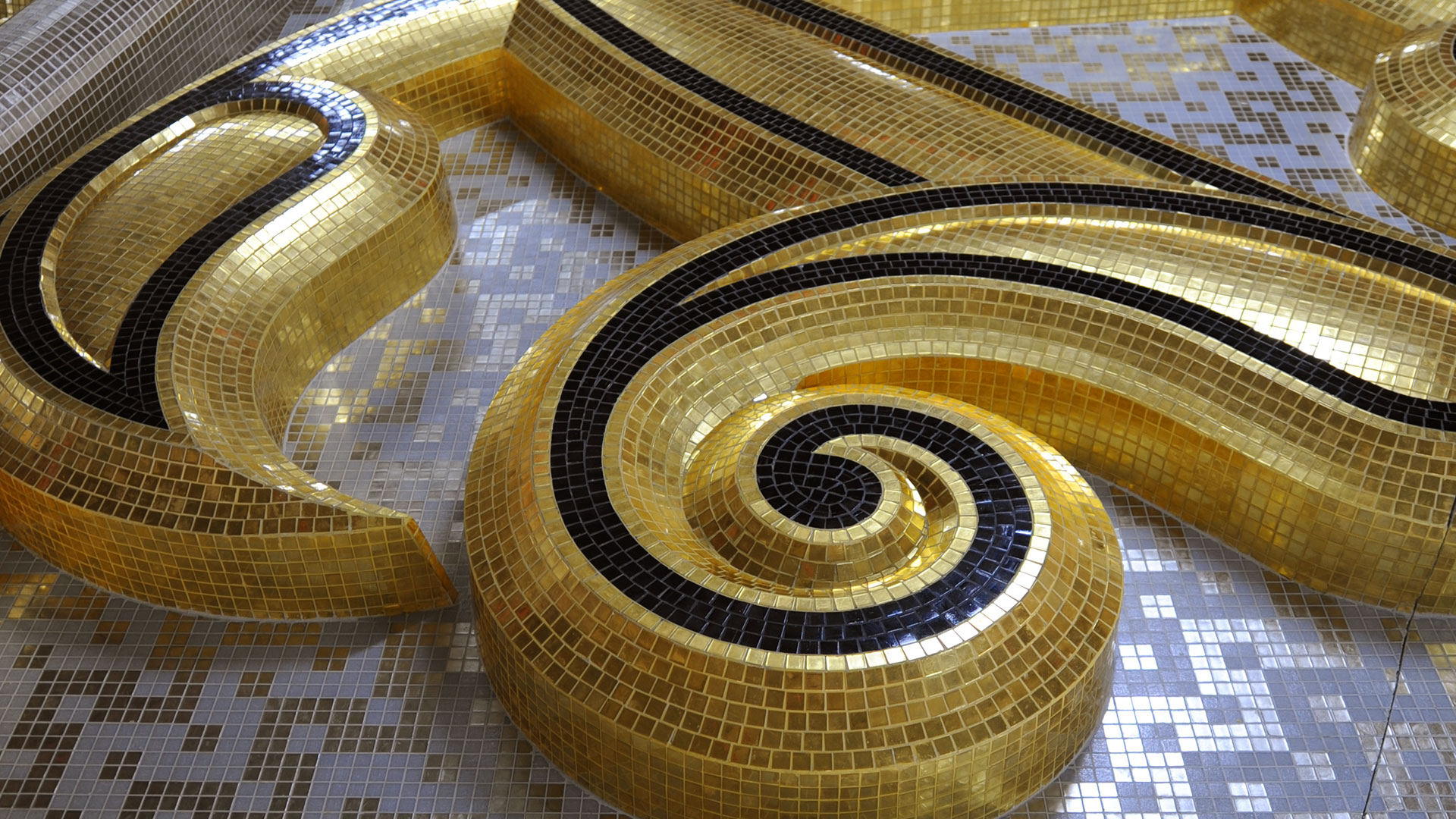

Although the composite materials used for the tower clock cladding are extremely durable, they need to be protected from harmful UV radiation. Because glass mosaic reflects UV light very efficiently and is highly decorative, the clock faces and other sections of the facade were covered with custom-made glass tiles. As daytime and night-time temperatures can fluctuate by up to 70 degrees Celsius, the tiles and adhesive have to be extremely resistant to thermal influences.

For the processing of high-strength glass and carbon fibre components, SL Rasch consulted with a boatbuilding company that specialises in racing yachts. The clock itself was implemented by the renowned tower clock manufacturer Perrot from the town of Calw in southwest Germany. This involved major challenges: the faces of the clock are about 450 metres above the ground and 43 metres high. The hands alone are 22 metres long, and an outstanding example of self-supporting structures: like the hull of a boat, their stiffness comes entirely from the outer shell – there is no load-bearing interior structure at all. In some places, they consist of up to 150 layers of carbon fibre laminate.

A concealed hatch in the clock face provides access to the hollow structures when the LEDs require maintenance. Because the carbon fibre hands have a total weight of 12 tonnes, the clock movement has to be extremely strong and robust. Made of premium-quality wheels, pinions and arbors and weighing 21 tonnes, it is the heaviest clock movement in the world. The tower clock is crowned by a “glass jewel” that resembles a faceted diamond. Solar collectors were installed in its tip to power the four clock units. The structure ends in a 45-metre-high spire topped by a golden crescent.

The space behind the clocks contains a cosmology research centre and public exhibition rooms. The four-storey facility informs visitors about the development and construction of the clock tower, the history of Islamic time measurement and the history of the Qur’an. The “glass jewel” contains the Lunar Center and the Makkah Time Institute – one of more than 50 time institutes worldwide. The clock introduced a second time standard in addition to Greenwich Mean Time. Now Muslims in Berlin, London, New York and Jakarta know exactly when Ramadan begins as the sun rises over Mecca, when they can break their fast after sundown or when to recite their five daily prayers while facing towards Mecca.